Industrial Automation refers to the use of sensors, robots , actuators in various industrial processes so that we get much better efficiency and the working labour required is low. Although the initial cost of setup of an automated industry is high, but the industrialists will surely be in profit if they apply the automation method as they can produce more no of goods in a limited time and also the quality of their products will increase as the human error in production is minimised.

Here are some of the industrial processes in which we can use automation:-

Welding:- Welding is one of the most important process in every manufacturing industry.Lets take an example of the automobile industry. Chassis - the supporting frame of a car needs a lot of welding to be done. We can't make the whole chassis of a car by just the casting process as it's too intricate. What we do is cast the individual parts of the chassis and then weld them together to get final chassis. Similarly there are many other industrial manufacturing activities that requires welding. Hence a lot of industries can use welding Robots instead of humans doing the welding process.This is because if Industries use Welding Robots , then the defects that arise due to welding will decrease and hence the quality of product can be enhanced.

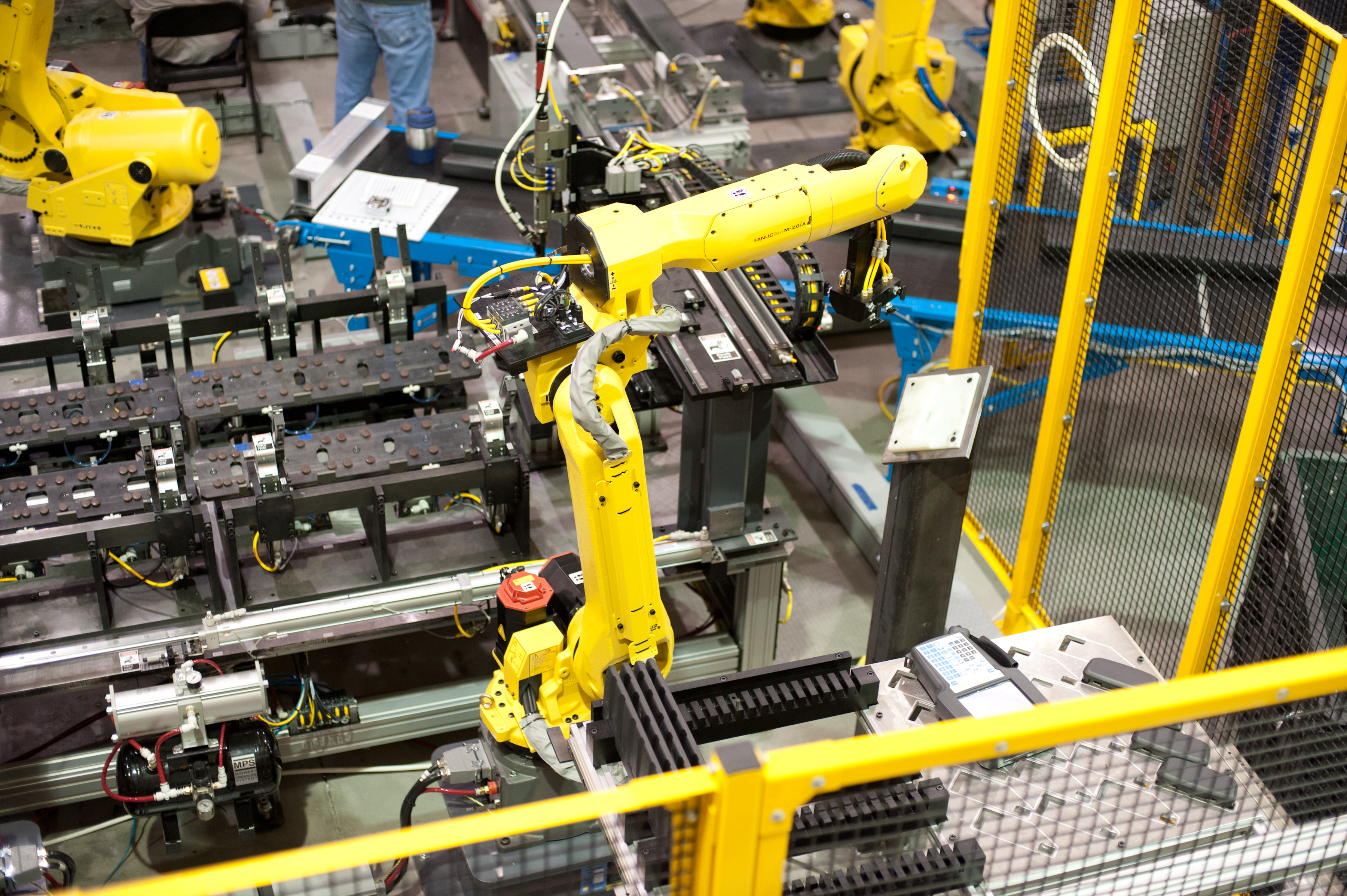

Assembling Robots:-

Assembling is the most important phase of a manufacturing process and it requires skilled labourers as various parts must be assembled as per the design. Robots can simplify this task as the final design can be loaded into robot's memory and based on the design , the robot can be coded to perform various assembling tasks.

The image shows a robot involved in automation of car assembly process

The image shows robot used in packaging.

Robotic Vision being employed for product testing Basically we must adopt Flexible Manufacturing System (FMS)for maximising the output of Industries. By using this method , we can effective maintain the flow of material through FML(Flexible Manufacturing Line)that's going to undergo a certain process in FMC's(Flexible Manufacturing Cells).

Some more places where the concept of automation can be applied:-

Effluent Treatment Plants(ETPs):- Every chemical Industry produces a lots of waste material called effluents which must be treated before dumping them into industries. These effluents are treated in effluent treatment plants. Even after treating the effluents through ETPs in first pass, there can still be presence of unwanted materials which can affect the river bodies in which this effluents are dumped. Also the temperature at which these effluents are thrown to the water bodies is a factor because aquatic animals cannot resist temperature difference of water. Water Quality sensors,temperature sensors can be used to check the water quality at the outlet of ETPs and if they don't meet the required criteria for the disposal, these can be sent back to the ETPs through other pipes automatically by operating valves and servo motors to control it. This can be a small step towards protection of environment.

Thermal Power Plants:- In thermal Power plants the majority of accidents are caused because of bursting of boilers mostly because there were some impurities in the water that was poured into it due to which excess temperature was required to heat the water in it and the material that was used to build the boiler was not able to withstand such high temperature. Automation can be used here by making use of temperature sensors ( the one which are able to measure high temperatures).If the temperature measured by this sensors go beyond 0.8 times the max temperature that can be withstanded by the boiler material , the heat supply to the boiler must be automatically cut off. By this we can ensure lesser accidents in Thermal Power Plants.