The merging of the words aviation and electronics, Avionics are all of the electronic devices and systems which perform individualized functions, used on any aircraft. Whether it is a military standard drone or a small hobby craft, it contains many electronic components which together achieve controlled flight. In this blog I’m going to talk mainly on the electronics aspect of the equipment used in small scale aircraft and drones.

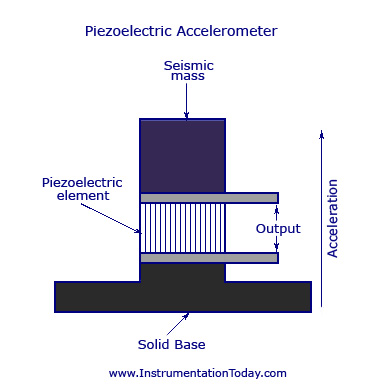

An accelerometer is a transducer that is used to measure the physical or measurable acceleration that is made by an object. The most commonly used device is the piezoelectric accelerometer. It makes use of a piezoelectric quartz crystal. Due to the special self-generating property, the crystal produces a voltage that is proportional to the accelerative force. The basic arrangement is shown in the figure above. When movement occurs in one direction the amplitude of voltage signal generated gives the amount of acceleration. Coupled with two more setups in two other axes’ give complete 3dimentional acceleration. Well known algorithms exist to calculate the speed increase or displacement based on this data. This type of device is called dynamic accelerometer and the movement of the object can be foreseen using it.

Nowadays, a new type of accelerometer called the Micro Electro-Mechanical System (MEMS) Accelerometer is being used as it is simple, reliable and highly cost effective.

A gyroscope is a device that is used to measure angular velocity. It is similar to accelerometer in working. More precisely called Vibration gyro sensors sense angular velocity from the Coriolis force applied to a vibrating element. the accuracy with which angular velocity is measured differs significantly depending on element material and structural differences. Here is an example of how gyroscope using Epson 's double-T structure crystal element works

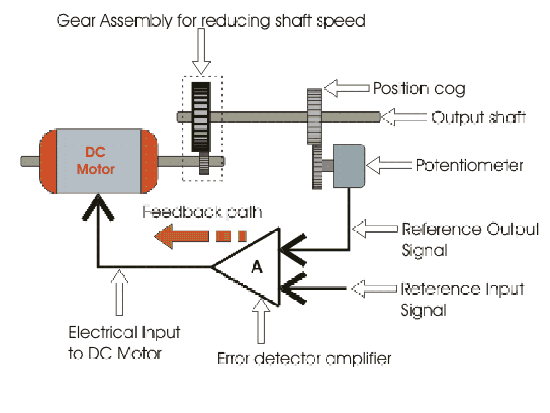

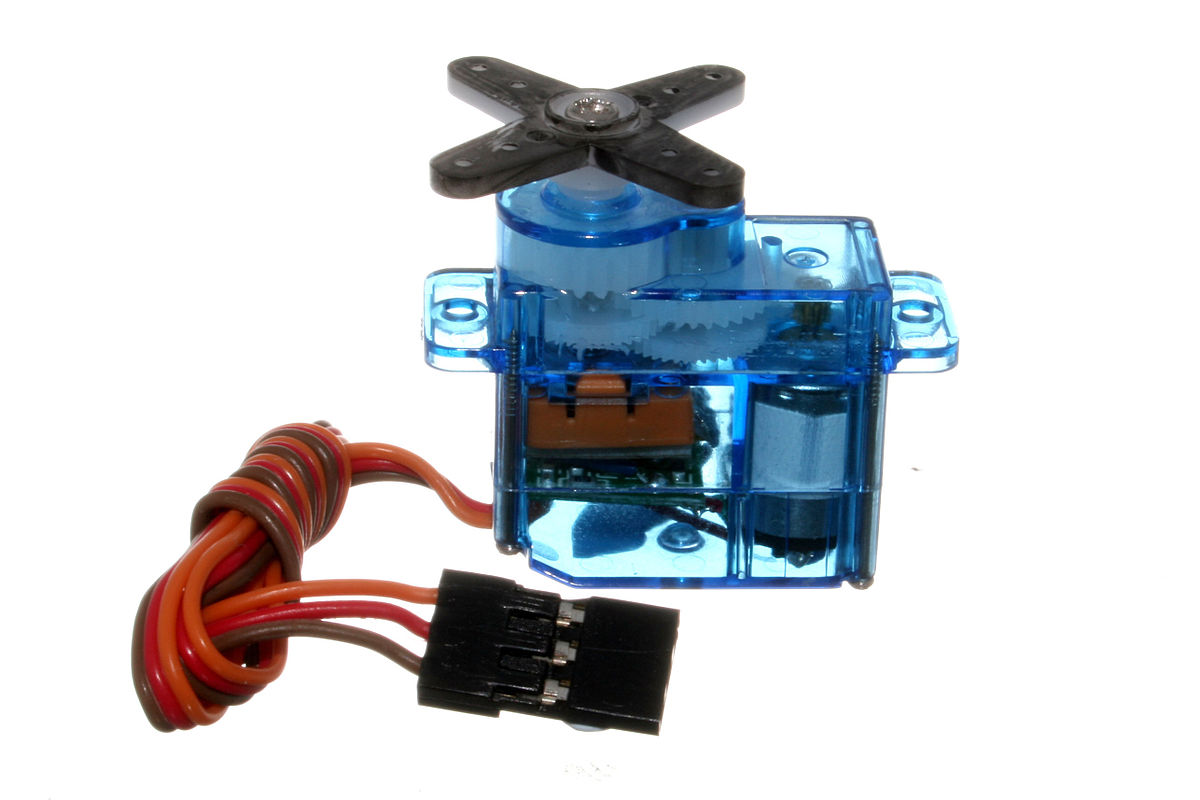

Servo motors are specially designed motors to be used in control applications of drones. They are used for precise position and speed control at high torques. It consists of a suitable motor, position sensor and a sophisticated controller. Servomechanism is basically a closed-loop system, consisting of a controlled device, controller, output sensor and feedback system.

Mechanical position of the shaft can be sensed by using a potentiometer, which is coupled with the motor shaft through gears. The current position of the shaft is converted into electrical signal by the potentiometer, and the compared with the command input signal. Command input is given according to the required position of the shaft. If the feedback signal differs from the given input, an error signal is generated. This error signal is then amplified and applied as the input to the motor, which causes the motor to rotate. And when the shaft reaches to the required position, error signal becomes zero, and hence the motor stays standstill holding the position.

In modern servo motors, electronic encoders (Gray code) or sensors are used to sense the position of the shaft.

ESCs are used to vary the speed of main motor that is used to provide the thrust for the aircraft. They work on the principle of Pulse width modulation. The control of motor speed is obtained by switching the power to the motor on and off in various ratios e.g. maximum throttle is permanently on, half throttle is on half time, off half time etc. This switching on and off is done many times a second. The speed at which the switching takes place has a large effect on overall efficiency.

Early speed controls used what is known as "frame rate" switching, which means that they switched approximately 50 times a second, the same rate as frames of information are delivered over the radio. Most modern ESCs switch at a much higher rate which makes them much more efficient i.e. they lose less power as heat in the controller. Switching rates around 3000 Hz (times a second) are about optimum. Anywhere between 1000 Hz and 5000Hz is acceptable.

Modern ESCs also contain a BEC inbuilt in them. A battery eliminator circuit (BEC) is an electronic circuit designed to deliver electrical power to other circuitry without the need for multiple batteries. A BEC-equipped ESC meant for airplane use often incorporates a low-voltage-cut off (LVC) circuit which can sense the voltage drop caused when the battery has little charge left in it. It then cuts the power to the 'drive' motor in order to provide the 'steering' servo(s) with enough power to be able to bring the model safely back to the operator. The power to the propeller would be cut but the operation of the control surfaces would be maintained in order to perform a dead-stick landing. Without this feature, all control would be lost when the battery expired, probably resulting in the destruction of the model. R/C BECs in their simplest form use a linear fixed voltage regulator.

In order to control a drone remotely, you must be able to communicate with it wirelessly. This is when circuits which convert electrical signals into radio signals and vice versa are used in avionics.

They are usually frequency modulated signal generators and demodulators. While controlling your drone it may so happen that another person’s signal may interfere with you. To avoid situations such as your drone being controlled by someone else’s remote control, devices use a unique identification code to identify a transmission on one particular radio frequency as the transmission it wants to receive. To do this, transmitters and receivers are paired using an RFID or a “radio frequency identification.” All information broadcast over RFID is prefixed with an RFID so that the receiver knows that the information it is picking up is for it. Along with this RSSI method is used to detect the distance of drone from controller and if it is going out of range.

Apart from this various circuits like power distribution boards and FPVs exists which give additional functionality to the drone. The field has advanced so much that autonomous intercontinental flight also is possible for a small-scale drone.