A breakthrough for bio-inspired technology.

Many natural organisms have the ability to repair themselves. Now, manufactured machines will be able to mimic this property. Researchers have created a self-healing material that spontaneously repairs itself under extreme mechanical damage.

Game-changing ideas begin by seeing the possibility for sustainable life reflected in the living system around us. Biomimicry is an approach to innovation that seeks sustainable solutions to human challenges by emulating nature’s time-tested patterns and strategies. The goal is to create products, processes, and policies which guide us to a new lifestyle that is sustainable and well adapted on earth over the long haul. Nature has incorporated within itself innumerous ways to not only grow back to life but also provide us immense knowledge and ideas to develop new and varities of solutions to many of the problems we are grappling with. Animals, plants and microbes are the consummate engineers. As the most intelligent species on earth, we started to notice such “miracles” and adapt them to engineer out solutions to problems related to various fields including machining, architecture, robotics, polymerizations etc.

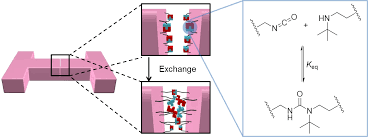

Self-healing materials are artificial or synthetically-created substances which have the built-in ability to automatically repair damage to themselves without any external diagnosis of the problem or human intervention. Although the most common types of self-healing materials are polymers or elastomers, self-healing covers all classes of materials, including metals, ceramics, and cementitious materials. These materials also include isocyanates monomers such as DCPD GMA epoxy resin, linseed oil and tung oil. By using the aforementioned materials for self-healing in coatings, it was proven that microencapsulation effectively protects the metal against corrosion and extends the lifetime of a coating.

The first self-healing materials were polymers with a kind of embedded internal adhesive, reported in 2001 by Scott White, Nancy Sottos, and colleagues from the University of Illinois at Urbana-Champaign. Since then, a variety of other self-healing materials have been developed.

Self-healing materials come in four main kinds:

The best-known self-healing materials have built-in microcapsules (tiny embedded pockets) filled with a glue-like chemical that can repair damage. If the material cracks inside, the capsules break open, the repair material "wicks" out, and the crack seals up. It works in a similar way to a type of adhesive called epoxy, which is supplied in the form of two liquid polymers in separate containers (often two syringes). When you mix the liquids together, a chemical reaction occurs and a strong adhesive (a copolymer) forms.

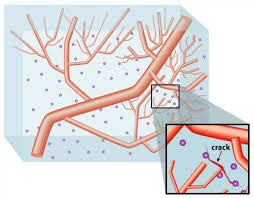

Our body has an amazingly comprehensive vascular system (a network of blood vessels of different sizes) that transport blood and oxygen for energy and repair. If damage occurs, our blood system simply pumps extra resources to the places where they're needed, but only when they're needed. Materials scientists have been trying to design self-healing materials that work the same way. Some have networks of extremely thin vascular tubes (around 100 microns thick—a little thicker than an average human hair) built into them that can pump healing agents (adhesives, or whatever else is needed) to the point of failure only when they need to do so. The tubes lead into pressurized reservoirs (think of syringes that are already pushed in slightly). When a failure occurs, the pressure is released at one end of the tube causing the healing agent to pump in to the place where it's needed.

Most of us know shape memory materials through relatively trivial everyday applications such as eyeglasses, made from alloys like nitinol (nickel-titanium), that flex exactly back to shape when you bend and then release them. Usually, shape memory works in a more complex (and interesting) way than this. Typically you need to heat (or otherwise supply energy to) a material to make it snap back to its original, preferred form. In practice, that might be an embedded network of fiber-optic cables similar to the vascular networks used in other self-healing materials except that, instead of pumping up a polymer or adhesive, these tubes are used to feed laser light and heat energy to the point of failure. That causes them to flip back into ("remember") their preferred shape, effectively reversing the damage.

Polymers don't always need sophisticated internal systems, such as embedded capsules or vascular tubes, to repair internal damage. Some of them break apart to reveal what we might think of as highly "reactive" ends or fragments that naturally try to join up again. Energized by either light or heat, these stray fragments naturally try to rebond themselves to other nearby molecules, effectively reversing the damage and repairing the material. Some break to expose electrically charged ends, which give the broken fragments a built-in electrostatic attraction. When damage occurs, electrostatic forces pull the fragments together, enabling the material to self-repair.

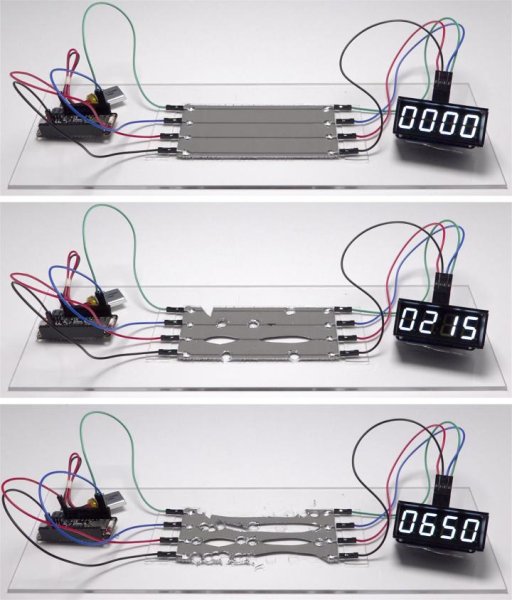

It's not difficult to imagine all kinds of applications for self-healing materials, from bridges and buildings that repair their own cracks to car fenders made from shape-memory polymers that automatically flex back to shape after low-speed collisions. The first self-healing materials we're likely to see in mass production will be paints and coatings that can better survive the weather and other kinds of surface wear-and-tear. Because the material also exhibits high electrical conductivity that does not change when stretched, it is ideal for use in power and data transmission. These soft-matter composite material is composed of liquid metal droplets suspended in a soft elastomer. When damaged, the droplets rupture to form new connections with neighboring droplets and reroute electrical signals without interruption. Circuits produced with conductive traces of this material remain fully and continuously operational when severed, punctured, or had material removed.

Self healing materials are gradually finding their way into everyday application.Imagine owning a car that can "heal" itself when met with an accident or when suffered scratches or bumps. One day, we might even have replacement parts for the human body that can heal themselves as well as their natural equivalents. At that point, the science of self-healing will truly have come round full circle. Trust scientists to reinvent nature!