Development Of Crawler Robot For Industrial Inspection

Abstract

Abstract

Aim

The primary aim is to design, analyze, and validate a large-scale (targeting 48-inch/1200 mm diameter pipelines) in-pipe robot capable of stable, long-distance, autonomous operation and inspection. Key objectives include achieving independent crawler adjustment, implementing a robust self-checking system using multiple sensors, and enabling active posture correction via differential speed control, particularly for operation in uncontrolled or fluid-empty pipeline environments.

INTRODUCTION

The integrity of large-diameter pipelines, critical infrastructure for oil and gas transport, is threatened by factors like aging, corrosion, and mechanical damage. While remote monitoring techniques like vibration analysis exist, direct internal inspection is often necessary but delayed due to accessibility challenges. In-pipe robots provide a solution by navigating these hazardous, confined spaces to perform inspections, thereby enhancing safety, accuracy, and efficiency. However, scaling existing robot designs to accommodate the large diameters (e.g., 48 inches) and long inspection distances (tens of kilometers) required for major pipelines presents significant hurdles. These include the substantial weight and size of advanced Non-Destructive Examination (NDE) equipment (like Magnetic Flux Leakage (MFL) and Ultrasonic Testing (UT)) needed for comprehensive structural assessment beyond simple visual checks. Consequently, large-scale robots must often operate autonomously without tethers, possess significant data storage, carry sophisticated sensor payloads, and maintain stability and correct posture over extended runs. This research addresses these specific challenges by proposing and analyzing a novel, independently adjustable crawler robot design tailored for large-diameter, long-distance pipeline inspection.

Literature Survey and Technologies Used :

A. Literature Survey: The field of in-pipe robotics, developed over two decades, encompasses various locomotion types including PIGs (Pipeline Inspection Gauges), wheeled, crawler, inchworm, and helical designs. Research specifically addressing larger pipelines includes work by Kim on optimizing navigation mechanisms and Mateos ,who proposed a six-wheeled-leg robot for cleaning and sealing applications. A key challenge identified is that simply scaling up smaller robot designs is often ineffective due to disproportionate increases in weight and complexity. For the long, often straight sections typical of large transport pipelines, autonomous operation is preferred. Wall-press crawler types are frequently chosen for their adaptability to varying internal pipe conditions and ability to traverse imperfections or obstacles. This work builds upon these concepts by focusing on independent adjustability and active posture control for enhanced stability in large pipes.

B. Technologies Used:

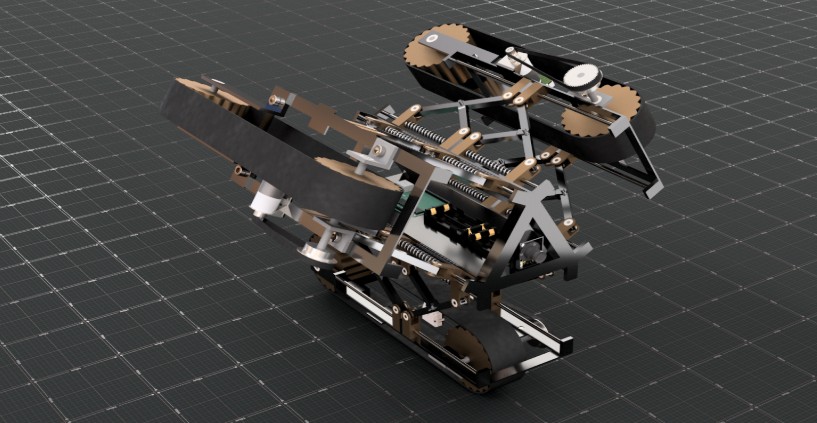

- Mechanism: A modular design comprising three identical crawler units radially attached (at 120° intervals) to a central body via articulated pantograph brackets. This allows each crawler to position independently radially.

- Actuation:

a. Radial Adjustment: Electric putters (linear actuators) integrated into each pantograph mechanism enable independent expansion and contraction, providing active control over the wall-pressing force.

b. Locomotion: 90W DC gear motors drive the tracks of each crawler module, allowing for independent speed control. The motors are mounted above the track bracket to minimize the overall width of the crawler unit.

- Sensing: A multi-sensor suite forms the basis of the self-checking system:

a. Pressure Sensors: Located between the loading wheels and the tracked bracket on each crawler, these continuously monitor the pressing force against the pipe wall. This data is crucial for maintaining optimal traction, preventing excessive force, and detecting potential jamming situations.

b. Encoders: Integrated with each drive motor, these provide precise, independent measurements of each crawler's speed and distance traveled. This enables differential speed control for steering and posture correction.

c. Laser Radar (Lidar): Mounted on the robot, Lidar performs real-time scanning of the pipe's internal geometry. It measures the pipe diameter, detects obstacles (like debris or weld seams), identifies changes in pipe shape (e.g., bends, dents), and helps map the internal terrain.

d. Accelerometer: Used to measure the robot's tilt and orientation (posture deflection) relative to gravity, providing feedback for attitude correction.

- Control System: An integrated self-checking control system utilizes the sensor data to achieve stable autonomous operation. It performs:

a. Pre-emptive Reaction: Uses Lidar data to anticipate obstacles or changes in pipe geometry.

b. Active Pressure Control: Adjusts electric putters based on pressure sensor feedback to maintain consistent wall contact.

c. Jamming Response: Can dynamically contract crawlers if excessive pressure (indicating a stuck condition) is detected.

d. Posture Correction: Implements differential speed adjustments between crawlers based on accelerometer and encoder data to counteract tilt or rotation.

- Materials: The robot frame utilizes lightweight aluminum, with Carbon Fiber Reinforced Polymer (CFRP) plates potentially used for structural components (details not specified).

Methodology :

- Robot Design & Kinematics: The robot features a distinct three-part structure per module: the central body connection, the pantograph bracket, and the crawler unit itself. The pantograph, actuated by an electric putter, provides a robust mechanism for independent radial adjustment, offering superior active pressure control and adaptability compared to passive spring-based or fixed screw mechanisms. This design allows the robot (weighing 45.8 kg) to operate within pipe diameters ranging from 950 mm to 1200 mm. The placement of the 90W gear motor above the track minimizes crawler width, essential for navigating potentially uneven internal surfaces.

- Self-Checking System Logic: The system operates proactively. Lidar scans ahead to identify potential issues (obstacles, diameter changes). Pressure sensors provide continuous feedback on wall interaction, allowing the controller to adjust the electric putters for optimal grip without excessive force. Encoders track individual crawler movement, while the accelerometer monitors overall robot posture. If Lidar detects an obstacle or pressure sensors indicate jamming, the system can react (e.g., adjust pressure, potentially contract a crawler). If the accelerometer detects tilt, the system uses differential speed control (adjusting individual motor speeds based on encoder feedback) to correct the posture.

- Mechanical Modeling & Analysis:

a. Internal Force Analysis (Static & Dynamic): A simplified 2D mechanical model (detailed in Figure 5 of the source document) was developed to analyze the internal forces acting between the central body, pantograph brackets, and crawler units. This analysis considers the robot's geometry, dimensions, and posture angles to calculate the necessary supporting forces and ensure structural integrity and stability under static (stationary) and dynamic (moving) conditions. Simulations were performed based on this model.

b. Differential Rotation Dynamics Model: To analyze the robot's ability to actively correct its attitude (rotation around its central axis), a dynamic model based on D'Alembert's principle was established (Figures 6 & 7, Equations 3-8 in the source document). This model mathematically describes how applying different speeds (v_{a1}, v_{b1}, v_{c1}) to the three independent crawlers generates tangential friction forces at the pipe wall. These forces create a net turning moment around the robot's longitudinal axis, allowing it to actively rotate and counteract any undesired tilt or misalignment during long-distance travel. This capability is crucial for maintaining the correct orientation of onboard NDE sensors.

- Active Adjustment & Control Strategy: The core strategy relies on the tight integration of sensor feedback and actuation capabilities. Real-time data from Lidar (geometry/obstacles), pressure sensors (contact force), encoders (speed/distance), and the accelerometer (tilt) is processed by the control system. This allows the robot to:

a. Maintain a central position within the pipe.

b. Adapt the pressure of each crawler independently to uneven surfaces.

c. React intelligently to detected obstacles (e.g., adjusting path or pressure).

d. Actively correct posture deviations using differential crawler speeds, ensuring stability and accurate sensor deployment over long distances.

Results

- Simulations: Static and dynamic simulations based on the mechanical models were successfully performed to analyze internal force distribution and validate the structural design under expected operating loads. (Specific quantitative results from simulations are not detailed in the provided text).

- Experimental Validation: Primary experiments were conducted using a prototype robot within a large-diameter (likely 1200mm) steel pipe section.

a. Stability: The experiments confirmed that the robot, utilizing its independent adjustment and control system, could operate stably within the pipe.

b. Endurance & Speed: The prototype demonstrated the capability to run continuously for over 65 minutes on battery power, achieving an average speed of 5.3 meters per minute.

Conclusions/Future Scope

Conclusions: This research successfully designed, modeled, and preliminarily validated a novel large-scale in-pipe robot incorporating three independently adjustable crawler modules. The use of electric putters for active pressure control, combined with a multi-sensor self-checking system (Lidar, pressure, encoders, accelerometer), enables robust operation. Crucially, the analysis and implementation of a differential speed control mechanism provide the capability for active attitude correction during motion. The methodology facilitates stable navigation and posture maintenance within large-diameter pipes, as confirmed by initial experiments demonstrating stable operation and reasonable endurance.

Future Scope: The primary future direction is the development towards fully autonomous, long-distance inspection missions in real-world large oil and gas pipelines, particularly under challenging uncontrolled conditions (e.g., presence of residual fluids, debris). This will necessitate:

- Further refinement and validation of the control algorithms, especially for complex navigation and obstacle negotiation scenarios.

- Integration and testing of specific NDE sensor payloads (e.g., MFL, UT) onto the platform.

- Extensive field testing in realistic pipeline environments to assess long-term reliability, robustness, and inspection data quality.

- Development of energy management strategies for extended autonomous operation.

References:

-

Kim, J.; et al. (2011) [Details related to optimal pipe navigation mechanism]

- Mateos, L.; et al. (2012) [Details related to six wheeled-leg robot concept]

- Cho, W.-H.; Kim, T.-H.; Yang, H. Normal-Force Control for an In-Pipe Robot According to the Inclination of Pipelines. IEEE Trans. Ind. Electron. 2010, 58, 5304–5310.

- Garber, M.; Wong, J. Prediction of ground pressure distribution under tracked vehicles—II. Effects of design parameters of the track-suspension system on ground pressure distribution. J. Terramechanics 1981, 18, 71–79.

- Keller, T.; Arvidsson, J. A model for prediction of vertical stress distribution near the soil surface below rubber-tracked undercarriage systems fitted on agricultural vehicles. Soil Tillage Res. 2016, 155, 116–123.

- Özdemir, M.N.; Kılıç, V.; Ünlüsoy, Y.S. A new contact & slip model for tracked vehicle transient dynamics on hard ground. J. Terramechanics 2017, 73, 3–23.

Report Information

Team Members

Team Members

Report Details

Created: April 7, 2025, 1:46 p.m.

Approved by: Joel Jojo Painuthara [Diode]

Approval date: None

Report Details

Created: April 7, 2025, 1:46 p.m.

Approved by: Joel Jojo Painuthara [Diode]

Approval date: None