Integration of ML methods in CFD of Propeller blades

Abstract

Abstract

Integration of ML methods in CFD of Propeller blades

AIM

This project seeks to revolutionize the design process of propellers by employing neural networks to optimize their geometry for maximum thrust and minimal power consumption. The proposed system harnesses the power of machine learning to intelligently navigate the complex design space, offering a faster, more cost-effective alternative to traditional simulation-based methods.

INTRODUCTION

In the recent evolution of fluid dynamics and machine learning, a fascinating trend has emerged: integrating artificial intelligence into traditional simulation methods. This convergence led to innovative projects like the optimization of propeller blades using CFD and neural networks. Here, physics-based simulations and data-driven models collaborate to enhance aerodynamic performance.

Computational Fluid Dynamics (CFD) is a powerful tool used to analyze fluid flow behavior around objects by solving complex mathematical equations numerically. In the context of propeller design, CFD helps in understanding the flow characteristics, thrust generation, and power consumption across different blade geometries and operating conditions.

Machine learning, particularly Artificial Neural Networks (ANNs), has emerged as a complementary approach by learning patterns from simulation data. By training on key parameters such as blade number, rotational speed, advance ratio, diameter, and efficiency coefficients, ANNs can predict critical outcomes like thrust and power with high accuracy, reducing the need for repeated, time-intensive simulations.

In this project, CFD simulations were first conducted to obtain detailed performance metrics of propeller blades. Using this dataset, an ANN model was developed that takes in parameters like B, N, J, D, P, Ct, Cp, and efficiency to predict thrust and power output. This approach combines the physical rigor of CFD with the speed and predictive capabilities of machine learning, leading to a smarter, faster propeller design workflow.

TECHNOLOGIES USED

Python

Ansys Fluent

LITERATURE SURVEY

PYTHON: Python is a high-level, general-purpose programming language. Its design philosophy emphasizes code readability with the use of significant indentation. It supports multiple programming paradigms, including structured, object-oriented, and functional programming.

ANSYS Fluent : is a powerful, general-purpose Computational Fluid Dynamics (CFD) software. Its design philosophy emphasizes flexibility and accuracy in simulating fluid flow, heat transfer, and chemical reactions. Fluent supports multiple modeling approaches, including steady-state, transient, laminar, and turbulent flows, enabling engineers and researchers to analyze and optimize complex fluid systems with precision.

METHODOLOGY

The presented system introduces an innovative approach to propeller thrust and power prediction by integrating machine learning with computational fluid dynamics (CFD) validation. A custom-built Artificial Neural Network (ANN) model was developed to predict aerodynamic forces, with simulation-based validation conducted using ANSYS Fluent. This methodology enhances predictive accuracy while reducing reliance on expensive experimental setups.

1. Dataset Collection

The initial dataset was sourced from the University of Illinois Urbana-Champaign (UIUC) Department of Aerospace Engineering, containing experimental wind tunnel measurements of propellers designed for small UAVs and model aircraft.

The dataset features include:

| B | Number of Blades |

| D | Propeller Diameter (inches) |

| P | Propeller Pitch (inches) |

| J | Advance Ratio |

| N | Propeller Rotational Speed (RPM) |

| CT | Thrust Coefficient |

| CP | Power Coefficient |

| η | Propeller Efficiency |

2. Preprocessing and Feature Engineering

To ensure compatibility and accuracy for machine learning, the raw dataset underwent extensive preprocessing:

Unit Conversion:

Propeller diameter (D) values were converted from inches to millimeters using:

Dmm = 25.4 × Dmm

Target Calculation:

Using standard aerodynamic equations, thrust and power were calculated:

Thrust = B × CT × ρ × (N/60)2 × Dmm4

Power = B × CP × ρ × (N/60)3 × Dmm5

[ where ρ = 1.225 kg/m is the air density. ]

Handling Missing Data:

Any samples with missing values were removed to maintain model integrity.

Feature Scaling:

All input features and output targets were scaled to a [0, 1] range using Min-Max normalization to accelerate and stabilize the ANN training process.

3. Artificial Neural Network (ANN) Modeling

Artificial Neural Network (ANN) Methodology:

- Prepare Input and Output:

- Features XXX = [B, N, J, D, P, Cₜ, Cₚ, η]

- Targets YYY = [Thrust, Power]

- Normalize both XXX and YYY using MinMaxScaler.

Split Dataset:

- Split normalized data into 80% training and 20% testing using train_test_split.

Build ANN Model:

- Initialize a Sequential model.

- Add First Hidden Layer: 16 neurons, ReLU activation.

- Add Second Hidden Layer: 16 neurons, ReLU activation.

- Add Output Layer: 2 neurons (for Thrust and Power), Linear activation.

Compile Model:

- Optimizer: Adam

- Loss Function: Mean Squared Error (MSE)

Train Model:

- Train the ANN using 100 epochs and batch size of 32.

- Use validation data for monitoring performance.

Predict and Evaluate:

- Predict outputs for the test set.

- Inverse transform the predicted outputs to original scale.

- Evaluate model performance using test loss.

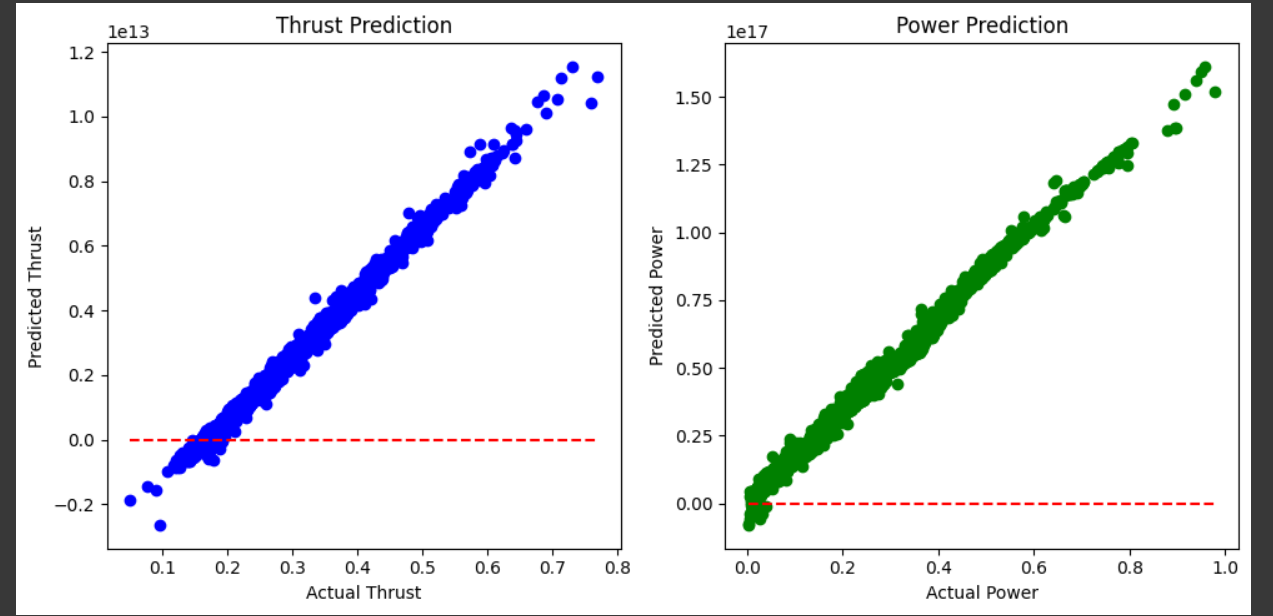

Plot Results:

- Plot Actual vs Predicted for both Thrust and Power.

4. Validation Using ANSYS Fluent

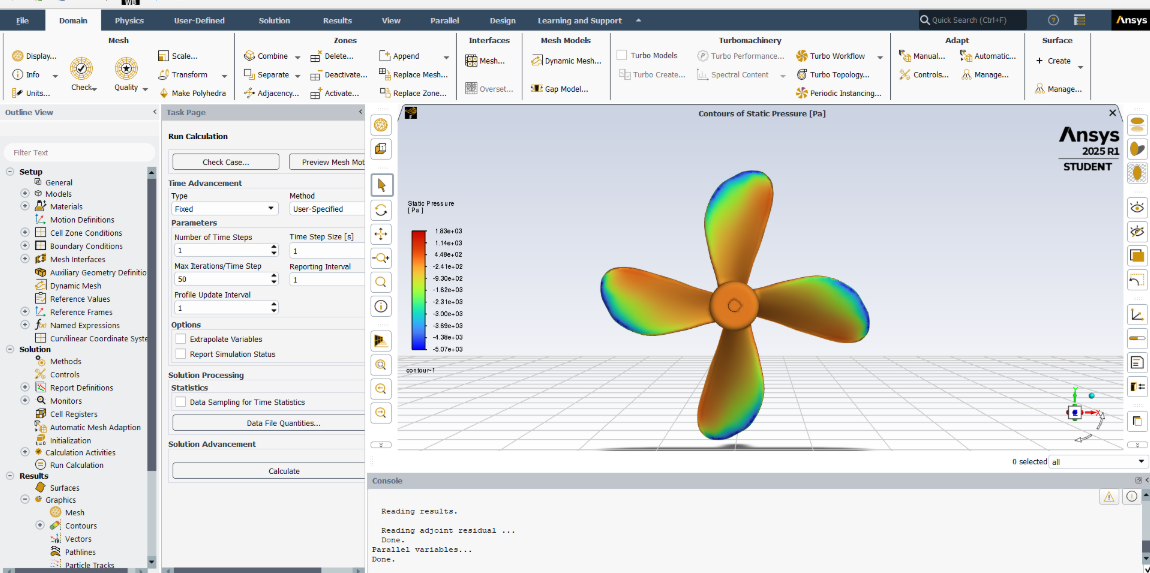

To validate the ANN model predictions, CFD simulations were conducted on a representative propeller geometry using ANSYS Fluent.

Simulation Setup:

- Airfoil Profile: NACA 63(4)-021

- Number of Blades: B = 4

- Propeller Diameter: D = 426 mm

- Rotational Speeds (N): 2000, 3000, 4000, 5000, 6000 RPM

- Velocity Inlet Conditions: 0.1, 0.5, 1.0, 1.5, and 2.0 m/s

Procedure:

- A 3D CAD model of the propeller was generated.

- The flow field around the propeller was simulated using the Moving Reference Frame (MRF) technique to capture rotational effects.

- Turbulence was modeled using the k-ω SST model to achieve high boundary layer fidelity.

Boundary Conditions:

- Inlet: Specified uniform velocity based on advance ratio (J).

- Outlet: Pressure outlet set at 0 Pa gauge pressure.

- Walls: No-slip boundary conditions applied to all solid surfaces.

Post-processing:

- Thrust and torque values were extracted from the simulations and compared directly to the ANN model predictions, ensuring consistency between computational and machine learning outputs.

RESULT

The prediction results demonstrate excellent agreement between the model outputs and the true thrust and power values. The scatter plots for both thrust and power show that the predicted values align closely with the actual values across the entire range, indicating that the model has successfully captured the underlying physical relationships.

Only minimal deviations are observed at higher magnitudes, which are expected and acceptable. The tight clustering of points along the ideal trend further confirms the model’s strong generalization and prediction capabilities.

Overall, the results validate the effectiveness of the developed model in accurately predicting thrust and power from the input parameters, supporting its reliability for future aerodynamic and propulsion system analyses.

FUTURE SCOPE

In the future, the model can be enhanced by integrating Physics-Informed Neural Networks (PINNs) to further improve prediction accuracy while maintaining physical consistency. Expanding the framework to handle 3D CFD simulations would allow for more realistic and complex propeller designs. Additionally, combining the model with optimization algorithms could automate the design of highly efficient propellers. Validating the predictions with experimental data will be crucial for making the system robust and ready for real-world applications.

REFERENCES

Dataset: https://www.kaggle.com/datasets/heitornunes/uiuc-propeller-database

https://www.kaggle.com/code/heitornunes/ct-prediction-xgboost/notebook

https://glingram.webspace.durham.ac.uk/wp-content/uploads/sites/104/2021/04/wind_turbine_design.pdf

https://github.com/jdtoscano94/Learning-Scientific_Machine_Learning_Residual_Based_Attention_PINNs_PIKANs_DeepONets/blob/main/Tutorials/PINNs/4_DiffusionEquation.ipynb

Acknowledgements

As executive members of IEEE NITK, we are incredibly grateful for the opportunity to learn and work on this project under the prestigious name of the IEEE NITK Student Chapter. We want to extend our heartfelt thanks to IEEE for providing us with the funds to complete this project successfully.

Report Information

Team Members

Team Members

Report Details

Created: April 7, 2025, 2:07 p.m.

Approved by: Ashish Pastay [Piston]

Approval date: None

Report Details

Created: April 7, 2025, 2:07 p.m.

Approved by: Ashish Pastay [Piston]

Approval date: None